Why Maryland Foundations Need More Than Just a Quick Fix

High pressure epoxy injection is a structural repair method that uses specialized pumps to inject epoxy resin into concrete cracks, creating a bond stronger than the concrete itself. When your Baltimore County basement wall develops that zigzag crack after a hard freeze, you’re not just dealing with an eyesore. You’ve got a structural issue that lets water reach your rebar, threatens your foundation’s integrity, and can turn a simple repair into a nightmare.

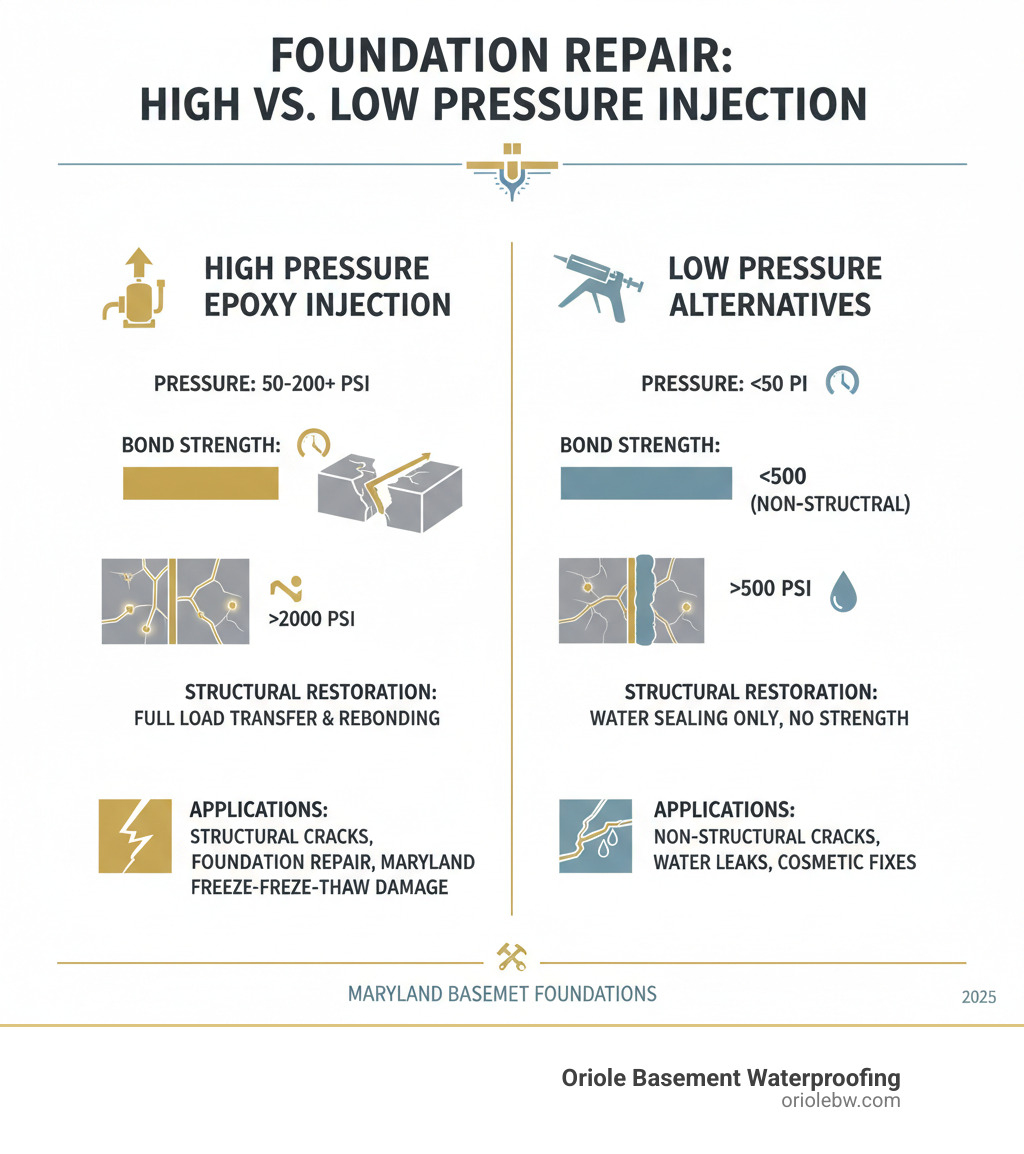

We’ve been fixing Maryland foundations for over 70 years, and we’ve seen what happens when homeowners try low-pressure foam injection or hardware store crack sealers on structural cracks. A proper repair uses ASTM C881 compliant dual-component epoxy resins, injected with high-pressure pumps to fully penetrate the crack. The bond strength of this properly injected epoxy exceeds 2,000 PSI. That’s stronger than most concrete. Polyurethane foam, on the other hand, seals water but doesn’t restore structural integrity.

The difference matters because Maryland’s freeze-thaw cycles and clay soils don’t just create cracks; they create moving cracks that need a solution as strong as the original concrete.

What is High-Pressure Epoxy Injection vs. Low-Pressure Methods?

When we talk about repairing concrete cracks, it’s crucial to understand the difference between high-pressure and low-pressure methods. High-pressure epoxy injection involves forcing a liquid epoxy resin into cracks to essentially weld the concrete back together, restoring its original strength. The bond can become stronger than the surrounding concrete, making it ideal for structural cracks where load transfer is critical.

Low-pressure injection, often using polyurethane foam, is excellent for water sealing. The foam expands to create a flexible barrier that stops leaks. However, it does not provide the same structural strength as epoxy. The choice depends on the problem: are we making the wall strong again, or just stopping a leak? For more on these methods, see this resource on Crack Injection for Concrete Basement Walls.

The Primary Applications and Benefits for Concrete Repair

For Maryland homeowners, the benefits of high pressure epoxy injection are significant. Our primary application is structural restoration. When foundation walls crack, epoxy injection welds them back together, restoring the concrete to its original strength, or often even stronger.

Beyond strength, there are other key benefits:

- Waterproofing and Preventing Rebar Corrosion: Epoxy creates an impervious seal that prevents water and contaminants from reaching the reinforcing steel (rebar). This prevents corrosion, a silent killer for concrete structures.

- Improved Durability: An epoxy-injected crack resists future movement and degradation from environmental stressors like our local freeze-thaw cycles.

- Increased Property Value: A structurally sound foundation is paramount. Addressing cracks with a proven method like high pressure epoxy injection protects your property’s value. Ignoring them, as we discuss in our guide on Cracked Basement Maryland: Causes and Solutions, can lead to major problems.

The Complete Guide to High Pressure Epoxy Injection

When you’re dealing with foundation cracks in your Maryland home, understanding high pressure epoxy injection can mean the difference between a repair that lasts decades and one that fails. After seven decades of fixing foundations across Baltimore City and surrounding areas, we’ve learned that the devil truly is in the details.

Identifying Cracks That Require Professional High-Pressure Epoxy Injection

Not every crack is a crisis, but some demand immediate attention. Structural cracks are the ones that require the power of high pressure epoxy injection. These are signs your foundation is under stress. Look for vertical cracks wider than 1/8 inch, horizontal cracks along basement walls, or diagonal step-cracks in block foundations. The biggest warning sign? Any crack that is actively growing.

Fine hairline fractures that haven’t changed are often non-structural, but they can still let in water. Our experience helps us tell the difference. We measure cracks, check for movement, and determine the right course of action. Sometimes we recommend carbon fiber straps alongside epoxy for bowing walls, creating a comprehensive solution. When there’s any doubt, we bring in our engineering partners. You can explore more about our approach in our guide to 5 Foundation Repair Methods.

The Anatomy of a Professional System: Resins, Pumps, and Ports

A professional high pressure epoxy injection system is a precision instrument. The heart of the system is the epoxy resin, an engineered material meeting strict ASTM C881 standards. For hairline cracks, we use low-viscosity epoxies that flow like water into the finest spaces. In damp Maryland basements, we choose epoxies with high moisture tolerance to ensure a proper bond.

Our dual-component injection pumps provide the muscle, mixing the resin and hardener with precise ratios just before injection. This ensures a consistent, reliable cure every time. Finally, injection ports are our entry points. We use surface-mount ports for most situations, but may use drill-in packers for deeper cracks or when higher pressures are needed. Each component is selected based on your specific situation, a level of detail you can learn more about in resources like the TxDOT Crack Repair Manual.

The Step-by-Step Professional Injection Process

Our high pressure epoxy injection process is methodical and precise. This isn’t about speed; it’s about permanence.

-

Preparation and Sealing: We start by thoroughly cleaning the crack to ensure a strong bond. Then, we install injection ports at regular intervals and apply an epoxy paste over the crack face. This paste acts as a surface seal, containing the resin during injection.

-

Injection and Monitoring: Starting at the lowest port, we inject the low-viscosity epoxy. We carefully manage the pressure, ensuring the resin fills the entire crack from the inside out. As epoxy begins to flow from the next port up, we know that section is full, cap the first port, and move to the next.

-

Curing and Finishing: After the injection is complete, the epoxy needs time to cure, a process that can take up to 24 hours to reach full strength. Once cured, we remove the ports and the surface seal, leaving behind a smooth, structurally sound repair that’s often stronger than the original concrete. This systematic approach ensures every repair meets our high standards. For more guidance, see our guide: What to Do: Foundation Needs Repair.

Critical Factors: Safety, Temperature, and Knowing the Limitations

Properly executing a high pressure epoxy injection requires respecting several critical factors. Safety is paramount; our technicians use appropriate personal protective equipment and ensure proper ventilation, especially in enclosed basements. The pressures involved demand careful management to prevent damage.

Temperature also plays a huge role. Heat makes epoxy flow easier but speeds up curing, while cold thickens it and slows everything down. We manage this by storing materials properly and sometimes pre-heating the work area to ensure a successful bond. It’s also vital to know the limitations. Epoxy injection won’t solve an ongoing settlement problem or fix severely corroded rebar without addressing the root cause first. The cost of professional injection varies, but the return on investment from preventing future structural failure is significant. For other leak solutions, explore our guide on Basement Wall Leak Repair.

Is Epoxy Injection the Right Choice for Your Foundation?

Seeing a once-cracked, unstable foundation transformed into a solid, dry space is what we love to do. That’s the change we’ve been creating for Maryland homeowners for over 70 years. High pressure epoxy injection isn’t right for every crack, but when it’s the correct solution, it’s incredibly effective. If you’re seeing structural cracks in your Baltimore City rowhouse or new fissures in your Baltimore County foundation, this method can save your home’s structural integrity.

The key is knowing when epoxy is the hero your foundation needs. That’s where our engineering-backed solutions and decades of local experience become invaluable. We don’t guess. We assess, measure, and recommend the repair method that will give you the longest-lasting results.

Your Next Steps for a Strong, Dry Foundation in Maryland

If you’re wondering whether that crack in your basement is cosmetic or something more serious, it’s time for answers. At Oriole Basement Waterproofing, we don’t just fix cracks; we solve the underlying issues that caused them.

Our holistic approach means we look at everything from drainage to soil conditions to determine if high pressure epoxy injection is the right tool. When we recommend it, it’s because we know it will create a repair stronger than the original concrete, and we back that with our lifetime transferable warranties. We’ve seen what happens when foundation problems are ignored. That’s why our service includes a thorough assessment, considering if walls need carbon fiber straps or if there are issues with a sill plate or support beam.

The best part? Your next step is simple. We offer free inspections throughout our service areas. Our certified technicians will explain what’s happening with your foundation in plain terms. No pressure, just honest answers.

Whether you’re in Baltimore City dealing with settlement cracks or in Harford County seeing new fissures, we’re here to help. For a comprehensive look at local foundation issues, our Foundation Repair Baltimore Guide is a great resource.

Ready to stop worrying? Get a free inspection for your foundation repair today! Your peace of mind is worth it.