That Unsettling Crack in Your Basement Wall

Crack injection repair is a professional method of filling and sealing concrete cracks by injecting specialized resins-typically epoxy or polyurethane-under pressure to restore structural integrity and prevent water intrusion.

Quick Answer: What You Need to Know About Crack Injection Repair

- Best for: Hairline to moderate cracks in poured concrete basement walls

- Materials used: Epoxy (for structural bonding) or Polyurethane (for waterproofing and flexibility)

- Process: Professionals inject resin under low or high pressure through surface-mounted or drilled ports

- Results: Permanently seals cracks from water and can restore structural strength

- When to call a pro: Actively leaking cracks, horizontal cracks, or cracks wider than 1/4 inch

You’re in your basement, and you spot it-a thin line running down the concrete wall that wasn’t there before. Whether it’s a tiny hairline crack or one that’s already leaking, it’s a sign that something has shifted or settled.

In Maryland, with our soaking spring storms and winter freeze-thaw cycles, these cracks rarely stay small or dry for long. The good news is that crack injection repair is a proven, professional solution that can permanently seal and stabilize most foundation cracks.

This guide will explain how professional crack injection works, which material is right for the job, and why it needs to be done correctly the first time. Whether you have a slow seep in Baltimore County or a bigger leak in Harford County, understanding your options is the first step to protecting your home.

Understanding Professional Crack Injection Repair

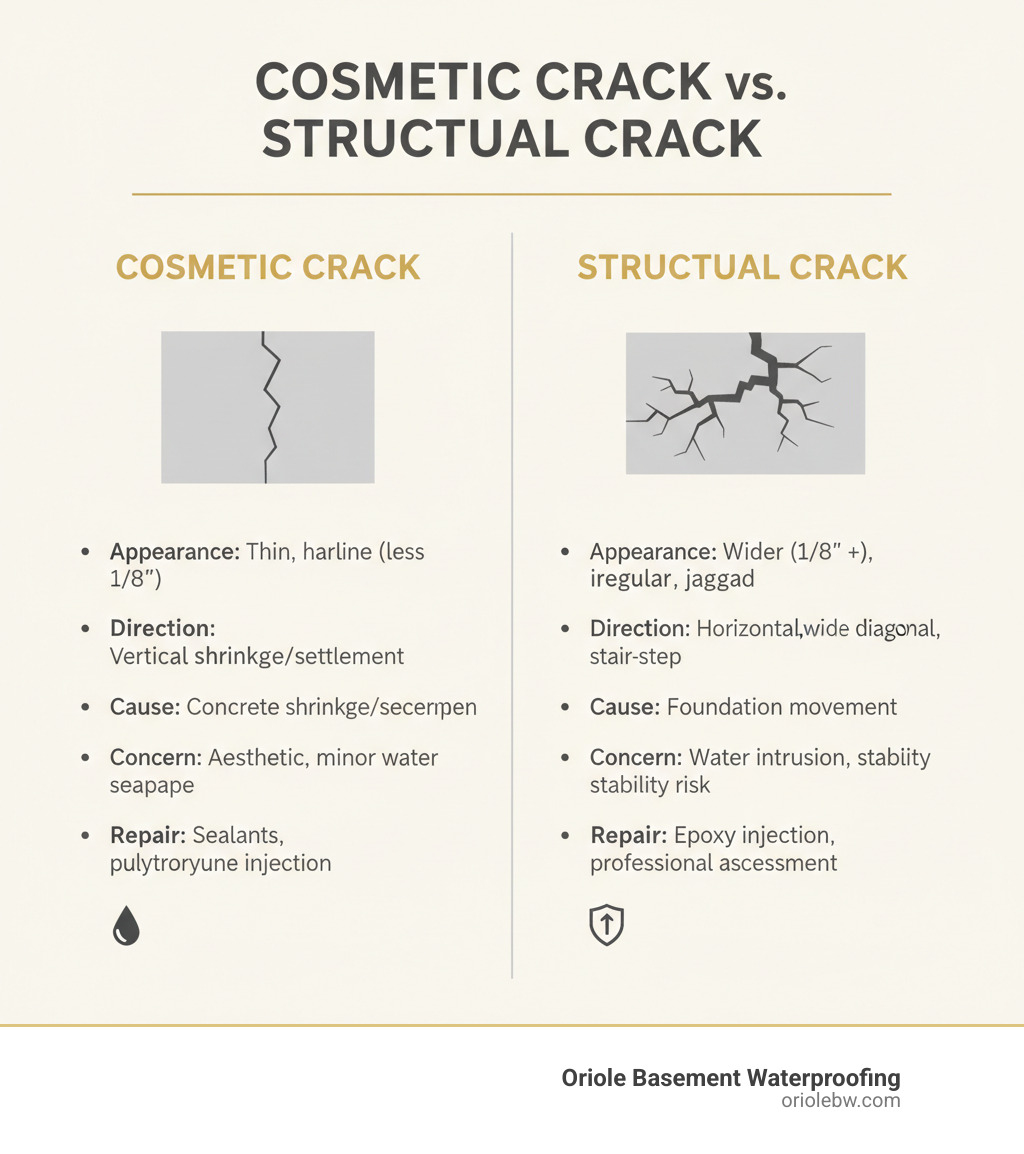

Not every crack means your house is in danger, but knowing what you’re looking at is the first step. Concrete cracks can range from a minor issue to a major problem.

Is It a Drip or a Danger? Identifying Your Crack

- Hairline cracks (less than 1/16 inch) are common as concrete settles. While not always a structural threat, even a tiny crack can let in moisture, which can freeze, expand, and make the crack worse over time.

- Wider cracks (over 1/16 inch) are more concerning. If you can fit a dime in it, it’s past the cosmetic stage and needs professional attention.

Direction also tells a story:

- Vertical cracks are usually caused by foundation settlement. They aren’t always structural emergencies, but they are a common source of water leaks.

- Horizontal cracks are a serious red flag. They indicate pressure from the soil outside pushing on your foundation wall. If you see a horizontal crack, especially if the wall is bowing, call a professional immediately.

- Diagonal and stair-step cracks point to differential settlement, where one part of your foundation is sinking faster than another. While crack injection is for poured concrete, these patterns in any foundation signal a larger issue.

So, is your crack structural? Look for these signs: movement (the crack is growing), location (horizontal cracks or cracks near corners are concerning), and water intrusion. If you also notice sticking doors, uneven floors, or cracks in your drywall, it’s time to call in the pros. Structural cracks are often caused by soil issues or poor drainage, while non-structural cracks are typically from concrete curing.

It can be tough for a homeowner to tell the difference. That’s why we offer free inspections throughout Baltimore City, Baltimore County, and Harford County. With over 70 years of experience looking at Maryland foundations, we can tell you exactly what you’re dealing with-no pressure, just honest answers.

For more detailed information on identifying cracks and what causes them in Maryland homes, check out our insights here: More info about identifying cracks

The Right Tool for the Job: Epoxy vs. Polyurethane Injection

Once we’ve identified the crack, we choose the right material for the repair. It’s not about which is “better,” but which is right for your specific problem. The two main materials are epoxy and polyurethane.

Epoxy is for structural strength. Think of it as welding the concrete back together. It cures into a rigid, hard bond that is often stronger than the concrete itself. We use epoxy to restore a foundation’s load-bearing capacity. It works best in dry cracks and also protects internal rebar from rust.

Polyurethane is for waterproofing. This flexible material reacts with water and expands (sometimes up to 30 times its volume) to fill every part of a crack. Because it stays flexible, it can handle minor foundation movement without breaking the seal. It’s the perfect solution for stopping active water leaks.

Here’s a quick comparison:

- Use Epoxy for: Structural bonding, restoring strength, and dry cracks. It’s incredibly strong but cures slowly, which allows it to penetrate deep into the crack.

- Use Polyurethane for: Flexible waterproofing, stopping active leaks, and filling large voids. It expands to fill the space, cures quickly, and works even when moisture is present.

When we see a dry, structural crack in a Baltimore County home, we’re likely using epoxy. If we find a crack with water streaming through it in a Harford County basement, we’ll use polyurethane to stop the leak fast.

Technical details like resin viscosity (thickness) and cure time are critical, and this is where our 70+ years of experience comes in. We know exactly which material and application method will provide the best, longest-lasting result for your home.

To learn more about the different foundation repair methods we use, visit: Learn about different repair methods

How Professionals Perform Crack Injection Repair

Professional crack injection repair is a precise process that separates a lasting fix from a DIY failure. It’s all about preparation and using the right equipment.

1. Preparation: First, we thoroughly clean the crack surface by wire brushing and vacuuming away any loose debris or old paint. This ensures a strong bond. We then install plastic injection ports along the crack, typically every 8 inches.

2. Sealing: We apply a temporary epoxy paste, called a cap seal, over the entire crack and the ports. This creates a contained channel, forcing the resin deep into the foundation instead of letting it leak out the front.

3. Injection: Using professional dispensing equipment, we inject the resin. We always start at the lowest port on a vertical crack and work our way up. This pushes air and water out, ensuring the crack is filled completely from the inside out. We continue injecting at each port until the resin begins to flow from the port above it.

We use either low-pressure or high-pressure injection depending on the crack. Low-pressure works for most common cracks, while high-pressure is needed for very fine hairline cracks or actively leaking ones to force the material into the tight space.

This methodical approach ensures full penetration and a permanent repair, which is why a professional job is so critical.

For a more in-depth technical guide to structural crack repair, you can check out this resource: A guide to structural crack repair

Ensuring a Lasting Fix: Best Practices and Challenges

A successful crack injection repair is one that lasts for decades. This means overcoming common challenges and following industry best practices.

One major challenge is actively leaking cracks. You can’t inject most epoxies into a wet crack. This is where we use hydrophilic polyurethane foam, which reacts with water to expand and create a waterproof seal, often using high-pressure injection to displace the water.

Another issue is previously repaired cracks. Old caulk or hydraulic cement can block the new resin. We often have to use high-pressure injection to bypass these obstructions and ensure our material fills the entire depth of the crack.

To ensure a repair lasts, we focus on these key steps:

- Address the Root Cause: Simply filling a crack isn’t enough if there’s an underlying issue like poor drainage. We assess the whole picture to provide a true solution.

- Proper Material Selection: We choose epoxy for strength and polyurethane for waterproofing. Using the wrong one guarantees failure.

- Thorough Preparation and Injection: Our meticulous process ensures the resin bonds properly and fills the crack completely.

- Carbon Fiber Reinforcement: For significant structural cracks, we often recommend adding carbon fiber straps over the repair. These provide extra strength to prevent future movement.

Safety is also a top priority. Our technicians use proper protective equipment and dust-control measures to protect our crew and your family from materials and silica dust.

This attention to detail is what 70+ years of experience looks like. We’re not just filling a crack; we’re providing a lifetime solution.

For more information on silica dust safety, check out: Learn about silica dust safety

Why a Professional Fix is Your Best Bet

You might be tempted to grab a DIY kit from the hardware store to save some money. We understand the impulse, but your home’s foundation isn’t the place to cut corners. A failed DIY attempt can turn a simple repair into a major headache.

The Risks of DIY vs. The Guarantee of a Pro

A DIY kit might seem cheaper upfront, but it doesn’t include industrial-grade materials, specialized equipment, or the experience to diagnose the problem correctly. Here’s what often goes wrong:

- Improper Material Choice: Using epoxy on a wet crack or polyurethane on a structural one will lead to failure.

- Incomplete Crack Fill: Without professional equipment, DIY injections often only seal the surface, leaving voids inside for water to exploit later.

- Making the Problem Worse: An improper repair can trap water, create new stress points, or mask a serious structural issue until it becomes much more expensive to fix.

Professional equipment provides the consistent pressure and precise mixing needed for deep penetration-something a caulk gun can’t replicate. Most importantly, DIY repairs come with no warranty. When it fails, you’re back at square one.

When you hire Oriole Basement Waterproofing, you’re investing in peace of mind. Our engineering-backed solutions ensure a durable, long-lasting fix that restores structural integrity and creates a permanent seal. A proper repair protects your basement from moisture, mold (for which we may refer you to specialists like Raven Mold if it’s not tied to active water intrusion), and damage to your home’s structural components.

Best of all, our foundation repairs come with a transferable lifetime guarantee. If a crack we fix ever leaks again, we’ll be back to make it right. That warranty also transfers to the next homeowner, adding real value to your property. You won’t get that from a hardware store kit.

Your Next Steps for a Strong, Dry Foundation

Finding a foundation crack is unsettling, but a professional crack injection repair is a powerful, permanent solution. The key is using the right material-epoxy for structure, polyurethane for waterproofing-and applying it with professional techniques.

Don’t wait for a small crack to become a big, expensive problem. Foundation issues only get worse with time. What might be a simple injection today could require extensive structural work with carbon fiber straps or beam replacement down the road.

Our team at Oriole Basement Waterproofing knows Maryland foundations. We understand how our local soils and weather affect homes in Baltimore City, Baltimore County, and Harford County. With over 70 years of experience, we are the region’s most trusted partner for creating strong, dry foundations, and we stand by our work with lifetime transferable guarantees.

If you’ve noticed a crack in your foundation, let our experts take a look. We provide thorough, no-pressure assessments and honest advice custom to your home.

Schedule your free foundation repair inspection today and get the peace of mind that comes with a healthy, worry-free basement.